Welcome to Agile Technologies

Laboratory Glassware washer and drier

Laboratory Glassware Washer and Drier

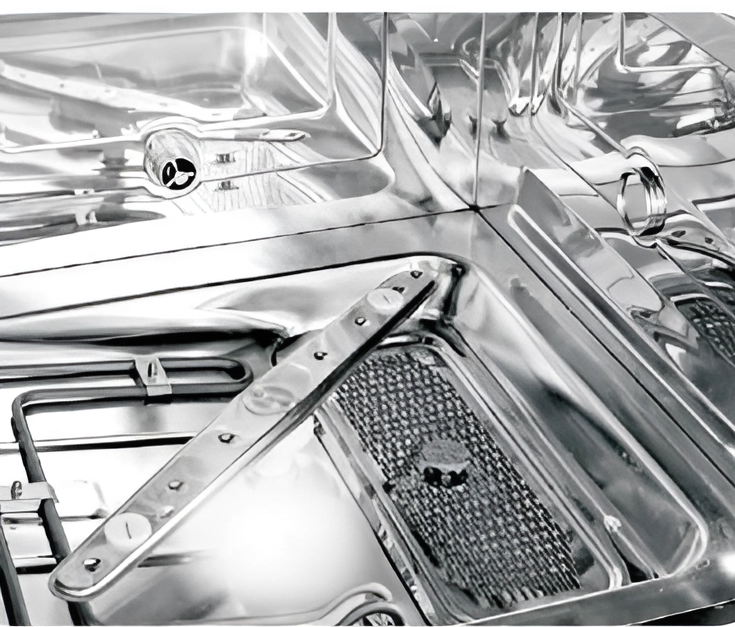

The Optima Econ is an front loading washer disinfec-

tor designed to handle a wide range of laboratory

glassware granting an automatic washing, thermodis-

infection and forced hot air drying treatment.

The PLC based control system is capable of storing

more than 50 washing programs: 20 standard pre-

programmed cycles and 50 additional adjustable and

password protected so the customer can configure

specialized programs for their independent needs. The

user can customize any parameter needed to a wash

cycle.

This unit has 2 separate washing and drying injection connections allowing the use of dedicated upper and lower washing carts. The upper level has telescapic bearing rails enabling the use of specific upper wash carts. The drop-down door provides a loading plat- form for lower and dual injection wash carts for a convenient loading and unloading job.

This unit has 2 separate washing and drying injection connections allowing the use of dedicated upper and lower washing carts. The upper level has telescapic bearing rails enabling the use of specific upper wash carts. The drop-down door provides a loading plat- form for lower and dual injection wash carts for a convenient loading and unloading job.

External WxDxH |

850mm x 650mm x 1450mm 33.46" x 25.59” x 57.08 |

Chamber WxDxH |

550mm x 500mm x 550mm 21.65" x 19.68" x 21.65 |

Door Passage WxH |

550mm x 500mm 21.65" x 21.65 |

Water consumption |

12 L per chamber fill |

Heat loss |

4'111 Btu/h (280 kcal/h) |

Sound level |

56.2 dB |

Standard Features

- Washing System:Two rotary spray arms, one on the bottom and one on the top of the chamber.Up to three more washing arms in the available wash carts Spray arms made of 5S 316L stainless steel.Easily disassemble washing arms for cleaning andmaintenance

- Forced Hot Air Drying System:Air circulation in the chamber, through the chamber washing arms and through the wash carts injection system and washing arms. F5 pre filter, fine filter and HEPA filter.2 kW heating elements provide up to 140°C air.Dryer German blower flow rate up to 200 m3/h.

- Direct Injection System:2 wash chamber connections for upper, lower and dual injection wash carts

- Circulation Pump:1 unit 450 l/min pump

- Fitler System: A three (3) stage filtration system helps protect recirculation and drain pumps from debris Filters can be easily removed for cleaning

- Steam Condenser:Prevents vapors from entering into the washing area at a set temperature programmable from: 0°C -95°C

- Chemical dosing:Two (2) peristaltic pumps provide precise addition of liquid chemical agents

- Electric Heater:6 kW electric heating elements providing heating up to 95°C Two independent temperature probes

- PLC based Control System:Possibility of up to 50 storable programs 20 standard programs, 50 user definable programs